What’s the next big thing in Industry 4.0 technology?

All of them

“ You can't apply technology in a vacuum and expect good result... You won't achieve any real benefits... unless you already have a process for planning and scheduling maintenance. ”

- Tim Close, Senior Expert, McKinsey

Fun fact: The average smartphone user downloads 75 apps, but spends 87% of their time on only five of them. Moral of the story: Useful trumps cool.

That applies to maintenance too. If a tool like 3D printing or augmented reality isn’t right for your team, it doesn’t matter if everyone else has it. It’s not going to work.

But we do know what Industry 4.0 tech does work: Integrations.

David Berger talking about the interconnectedness of the modern factory

Integrations connect one system to another, like a CMMS to equipment sensors or an ERP. They aren’t new, but they’ve gotten faster, less complicated to install, and smarter.

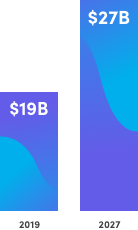

The market for AI in manufacturing is expected to jump from $19 billion in 2019 to $27 billion by 2027.1

That answer isn’t going to blow any minds. But the magic of integrations is not in what they are, but in what they do, which is combine data you already have, make sense of it, and use it to uncover opportunities to improve operations. Integrations help you get data quickly and accurately. They also sync workflows so processes can run smoothly.

This helps you move a lot closer to something even more exciting: Artificial intelligence. Access to high-quality data and the ability to turn it into action are two key ingredients of AI. Integrations provide both.

29% of AI implementations in manufacturing are for maintaining machinery and production assets2

So if you’re looking for AI’s origin story, look at integrations. It might not have the same ring to it as self-healing robots, but it’s a lot more practical.

Maintenance data has always been better at attracting dust than action. Until now.

See how Fiix has changed the game

A practical guide to Industry 4.0 and maintenance

Learn how IIoT, AI, big data, and more fit into your maintenance program.

Read moreA blueprint for what’s next in maintenance

This webinar offers tips for maintenance teams to get comfortable doing business-as-unusual.

Read moreHow to improve maintenance by tying your operations together

Explore three software integrations that can take your facility to the next level.

Read more